41-532 Waikupanaha Street, Waimanalo Hawaii 96795

(808) 259-9888

Mon-Fri: 7:00am - 3:00pm, Sat-Sun: Closed

About Us

Biosocks Hawaii was founded on the premise that solving age-old problems with innovative and bio-remedial solutions is good for both business and the earth. We have built our technology from the ground up through rigorous testing at our 35 acre independent research facility located in the mountains of Hawaii.

WHAT WE DO

Biosocks Hawaii develops new and innovative technologies that replace outdated, costly, and ineffective erosion and sediment control Best Management Practices (BMPs). When introducing new BioSolutions, our aim is to ensure our products achieve the following:

- Provide bioremediation of polluted stormwater

- Conserve natural resources & reduce the carbon footprint

- Reduce waste streams by using locally produced greenwaste

- Support wildlife habitat & remain low-impact on the ecosystem

- Increase installation efficiencies & reduce overall labor costs

- Minimize commercial fertilizer & pesticide requirements

- Protect waterways and maintain the quality & productivity of soil

WHY WE DO IT

While soil erosion has taken place since the beginning of time, modernization and commercial land development has placed new levels of strain on our earth’s natural resources.

The purpose of EnviroTech BioSolutions™ is straight forward, to protect our world’s fragile ecosystem from the potentially damaging effects of development and construction. By making bio-engineered solutions readily available, we can help preserve our delicate environment for our future generations.

Why Should You Choose Us?

Water Barrier

Rapid installation during severe weather events increases ability to protect life and property.

Area Drain Protection

No trenching required, quick installation, low maintenance, easy removal...

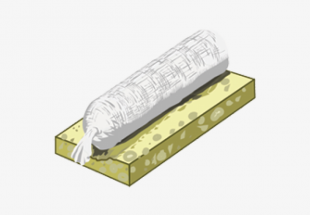

Stockpile Containment

No trenching required, quick installation, low maintenance, easy relocation, can be installed during storm events.

Shoreline & Streambank Protection

Aesthetically appealing alternative to “Hard Armor”.