41-532 Waikupanaha Street, Waimanalo Hawaii 96795

(808) 259-9888

Mon-Fri: 7:00am - 3:00pm, Sat-Sun: Closed

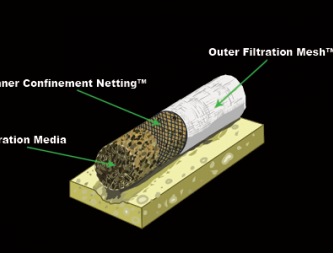

BioSock Pro™

Description:

The 12” nominal diameter BioSock Pro™ compost filter sock is a robust BMP device that is extremely capable in multiple application. The Patent Pending SynergyNetTM construction enables customization of the sock to achieve specific levels of strength, containment, filtration, rigidity, and bio-degradation. The BioSock Pro™ does not Require trenching and can installed on almost any terrain, including frozen ground and hard surfaces.

Applications:

- Perimeter Protection

- Area Drain Protection

- Curb Inlet Protection

- Stockpile Containment

- Check Structure Device

- Outlet Pipe Scour Prevention

- Streambank Protection

- Shoreline Protection

Benefits:

BioSock Pro™ compost filter socks represent Best Available Technology (BAT) standards as set forth under the National Pollutant Discharge Elimination System (NPDES) guidelines. Compost filter socks are an effective replacement for BMPs such as slit fence as determined by United States Environmental Protection Agency (EPA) research which reflects; (1) their ability to provide three-dimensional filtration of stormwater runoff, (2) their ability to facilitate bio-remediation of stormwater which can effectively remove petroleum products, heavy metals, pesticides, herbicides, nutrients, bacteria, and other pollutants, and (3) their economically achievable installation costs (EPA research has demonstrated that compost filter sock installations typically cost less over the life of a construction project than traditional BMP installations).

Silt Fence Vs. BioSock™

INSTALLATION

Silt Fence

- Requires disturbing the ground

- Requires trenching & backfilling

- Difficult to install properly

- Impossible near tree roots

- Can not be installed on frozen ground

BioSock™

- Low-Impact installation

- No trenching or backfilling required

- Easy and reliable installation

- Can be installed over tree roots

- Easily installed on frozen ground

EFFECTIVENESS

Slit Fence

- Clogs prematurely and dams water causing flooding and BMP failure

- Doesn’t filter fine sediment

- Does not stop petroleum, heavy metals, bacteria, and other pollutants from leaving the jobsite

- Can not be moved to allow for equipment access material deliveries, etc.

BioSock™

- Allows water to flow through and prevents premature BMP failure

- Effective at filtering fine sediment

- Protects the Environment, Bio-Remediates and removes petroleum, heavy metals, bacteria, and other pollutants

- Easily moved to allow for equipment access, material deliveries, etc.

MAINTENANCE

Slit Fence

- Easily damaged by wind and UV

- Destroyed by trucks and construction equipment

- Repairs require trenching, staking, and distributing the earth

- Requires frequent replacement

BioSockTM

- Withstands wind and UV

- Can handle encounter with trucks and heavy equipment

- Repairs can be done without trenching or disturbing the ground

- Typically lasts the life of the project

REMOVAL

Slit Fence

- Requires disturbing the ground, opening Trenches, and backfilling trenches

- After Slit Fence is removed all disturbed ground requires immediate stabilization and re-vegetation

BioSock™

- Ground is not disturbed during the BioSock™Netting/Mesh removal

- The compost infill previously contained within the BioSock™ is spread in-site and used as a soil amendment

COSTS

Slit Fence

- Lower initial cost, but higher overall project cost

BioSock™

- Higher initial cost, but lower overall project cost

12" BioSock™

Description:

The 12” normal diameter BioSock™ compost filter sock represents the latest in environmentally sustainable BMP technology and is capable in multiple applications. The BioSock™ does not require trenching and can be installed on almost any terrain, including hard surfaces that have roots and rocks.

Applications:

Perimeter Protection, Area Drain Protection, Curb Inlet Protection, Stockpile Containment, Slope Interruption, Device, Check Structure Device.

Technical Specifications:

| Construction | Composite-Layered Tubular Knit | |

| Chemical Reaction | Inert to most soil chemicals including Alkaline, weak acids and salt | |

| Properties | Fiber Material | Polypropylene Multi-filament |

| Filament Count | 60-120 | |

| Color | Black | |

| Melting Point | 330 F | |

| UV Protection | Photodegradable/UV Stabilized | |

| UV Resistance ASTRM D4355 | 150 Hours 100% 300 Hours 96.5% 500 Hours 89.5% | |

| Approx. Life Expectancy* | 18-24 Months | |

| Specific Gravity | .91 g | |

| Strength Properties | Static Puncture ASTM D6241 | 2400 N |

BENEFITS:

BioSock™ compost filter socks represent Best Available Technology (BAT) standards as set forth under the National Pollutant Discharge Elimination System (NPDES) guidelines. Compost filter socks are even an effective replacement for BMPs such as slit fence as determined by United States Environmental Protection Agency (EPA) research which reflects; (1) their ability to provide three-dimensional filtration of stormwater runoff, (2) their ability to facilitate bio-remediation of stormwater which can effectively remove petroleum products, heavy metals, pesticides, herbicides, nutrients, bacteria, and other pollutants, and (3) their economically achievable installation costs (EPA research has demonstrated that compost filter sock installations typically cost less over the life of a construction project than traditional BPM installations).

LEED ® Points & BioSock™

BioSock™ and LEED Certification Points:

The BioSock™ line of compost filter socks can help contribute towards a building’s LEED certification in a number of different categories. The major categories of the USGBC rating system and potential points achievable with the BioSockTM system include the following:

Sustainable Sites:

Stormwater Design: Quality Control – SS Credit 6.1 – BioSock™ installations can prevent a post-development stormwater discharge peak rate associated with the building’s footprint from exceeding that of pre-development and reduce stormwater discharge. The BioSock™ system is considered as stormwater treatment through is ability to remove suspended solids and other pollutants.

Potential Points: 1 to 2 points (depending on the overall percent of recycled project materials included in the project)

Materials and Resources:

Recycled Content – MR Credit 4.1 – The BioSockTM is made from 99% post-consumer recycled materials and can be applied towards the goal of 5% to 10% of the total value of project materials originating from recycled material. Potential Points: 1 to 2 points (depending on the overall percent of recycled project materials included in the project)

Regional Materials – MR Credit 5.1 – The BioSockTM system is manufactured locally thus the system can contribute toward having 20% to 50% of a building’s materials manufactured within a 500-mile radius. Since the BioSockTM is comprised or locally sourced post consumer recycled products, the BioSockTM can contribute to the 50% extracted regionally credit.

Potential Points: 1 to 2 points

Innovation and Design Process:

The BioSock™ is an Erosion Control 2.0 technology that effectively replaces conventional technologies that are outdated and ineffective. The environmentally friendly BioSockTM system may qualify for innovation and design credits by its ability to harness the power of recycled greenwaste to achieve the following advantages over conventional erosion and sediment control technologies:

- Reduces runoff and non-point source pollution

- Conserves water

- Improves soil quality and retards erosion

- Improves groundwater recharge

- Conserves fossil fuels

- Reduces construction waste stream

- Conserves landfill space

- Reuses waste materials

- Supports wildlife habitat

- Supports local ecology

Potential Points: 1 to 2 points

In Summary:

The BioSock™ system can contribute up to 7 points towards LEED certification, almost 25% of the total need to Certify. For more information on the BioSock™ system, visit www.biosockshawaii.com, send us as email at admin@biosockshawaii.com or call us at (808)259-9888

COMPARISON OF PERIMETER CONTROL BEST MANAGEMENT PRACTICES (BMPs)

| BioSock™ | Silt Fence | Straw-Filled Wattle | Coir Filled Log | Synthetic Fiber Log | Rubber-Filled Wattle | |

|---|---|---|---|---|---|---|

| EPA Approved BMP for NPDES Phase II | YES | YES | YES | YES | NO | NO |

| CFM per .25 Acre / 200 Device Length | .5 | .25 | .25 | .25 | NO DATA | NO DATA |

| LEED Point Eligible | YES | NO | SOMETIMES | NO | YES | YES |

| Trenching Required | NO | YES | YES | YES | YES | NO |

| Complexity of Installation | LOW | HIGH | MEDIUM | MEDIUM | MEDIUM | |

| Labor Required to Install | LOW | HIGH | MEDIUM | MEDIUM | MEDIUM | |

| Bio-Remediates Oil | YES | NO | NO | NO | NO | NO |

| Bio-Remediates Hydrocarbons | YES | NO | NO | NO | NO | NO |

| Bio-Remediates Pesticides | YES | NO | NO | NO | NO | NO |

| Bio-Remediates Bacteria | YES | NO | NO | NO | NO | NO |

| Bio-Remediates Heavy Metal | YES | NO | NO | NO | NO | NO |

| Overall effectiveness | HIGH | LOW | MEDIUM | MEDIUM | HIGH | HIGH |

| Maintenance Requirements | LOW | HIGH | MEDIUM | MEDIUM | MEDIUM | MEDIUM |

| Functional Longevity | 18-24 MOS. | 4-6 MOS. | 8-12 MOS. | 18-24 MOS. | 24 MOS | 36 MOS |

| Complexity of Removal | LOW | HIGH | MEDIUM | MEDIUM | MEDIUM | MEDIUM |

| Removal Waste Stream | LOW | HIGH | HIGH | HIGH | HIGH | HIGH |

| Soil Stabilization Required after Removal | NO | YES | NO | NO | YES | YES |

| Potential for BMP Failure during Project | LOW | HIGH | HIGH | MEDIUM | LOW | LOW |

| Re-Locatable & Movable | YES | NO | YES | YES | YES | YES |

| Overall Effectiveness | HIGH | LOW | MEDIUM | MEDIUM | HIGH | HIGH |

| Overall Price Installation | LOW | HIGH | MEDIUM | HIGH | HIGH | HIGH |